Enhance your weighing and force monitoring systems with Loadtech’s range of reliable and rugged accessories. These add-on items are designed to complement your load cell instrumentation and ensure optimal performance, protection, and visibility in demanding industrial environments.It is widely used in precise, low to medium capacity weighing applications - especially where compact and sensitive instrumenation is required.

Using extra add-ons like large displays, junction boxes, and surge protectors in your load cell systems is not just about added convenience — it’s about maximizing performance, safety, reliability, and user experience.

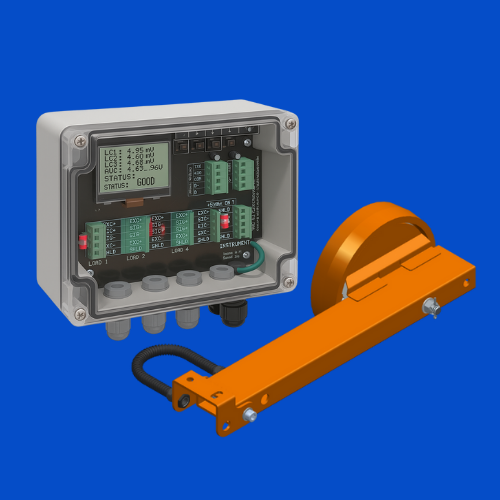

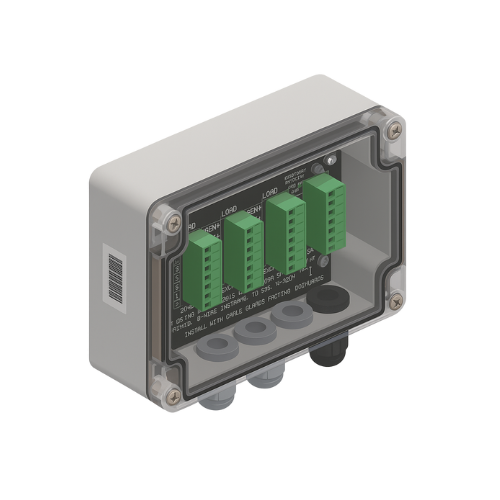

The load cell junction / summation box allows for easy connection / summation of up to 2 load cells to be connected in parallel to the load cell instrumentation.

The load cell junction / summation box allows for easy connection / summation of up to 4 load cells to be connected in

parallel to the load cell instrumentation.

The SMART load cell junction/summation box connects 1–4 load cells in parallel to host instrumentation, continuously monitoring each cell and excitation voltage. If a fault occurs—or if power is lost—it de‑energizes a relay to prevent incorrect weighing. It can be powered directly from the host’s excitation supply or via an external source

The LT1400 (4-digit) and LT1401 (6-digit) intelligent 7-segment displays are designed for industrial environments requiring clear, distant-readable numeric indicators. With 57mm (2.3″) high-brightness digits, it is suitable for:

Remote display of process inputs (e.g., temperature, pressure, level)

Weighing systems

General industrial monitoring applications

These displays can be wall-mounted using the aluminum enclosures with flanged plastic ends

57mm 2.3” Extra Large 7-segment intelligent display, Excellent visibility even at 25m viewing distance

4 or 6 digit model available, Rugged aluminium enclosure with flanged side plastic ends

RS232 and RS485 serial interfaces standard

Various protocols and software libraries available*

Software service available for protocol modifications*

Over/under range and communication error messages

Wide input supply voltage range of 12 to 30Vdc with built in voltage reversal and over voltage protection for harsh environments.

Transmit and Receive LEDS for RS232 and RS485 for in the field communication diagnostics

The LT1410 (4‑digit) and LT1411 (6‑digit) extra-large 7‑segment displays deliver crystal-clear readings from up to 50 m. Housed in rugged IP65 powder‑coated steel enclosures, they’re ideal for remote monitoring in demanding environments—perfect for displaying process values (e.g., temperature, pressure, level), weighing systems, and industrial indicators.

100 mm (4″) ultra-bright digits with visibility up to 50 m

Built-in RS232 and RS485 serial ports with support for multiple and custom protocols

Rugged IP65 powder‑coated steel enclosure for harsh environments

Easy-to-navigate menu system for configuring communications and display settings

Standard protections and alerts for over/under-range and communication errors

Wide 12–30 V DC supply with built-in over-voltage and reverse-polarity protection

Optional enhancements: universal mains input (90–265 VAC), RTC, and 2.4 GHz radio modem

RS232/RS485 TX/RX LEDs and field-upgradable firmware via RS232

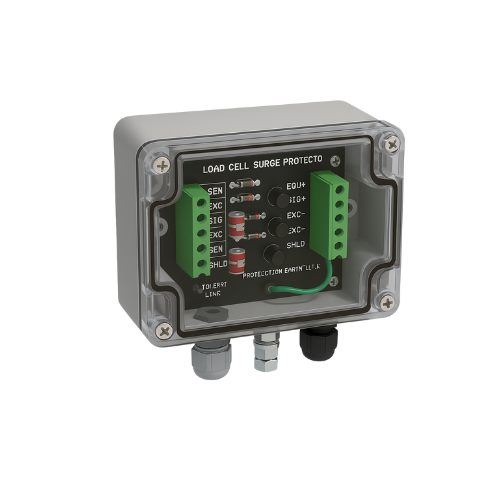

The LT1260 load cell surge protector safeguards weighing systems against severe over-voltage and high-current impulses. Installed between junction boxes and measurement instruments—and grounded via an external M8 stud—it provides robust protection for both 4‑ and 6‑wire load cell setups in challenging environments.

Triple-stage protection for signal, excitation, and shield lines:

3‑terminal gas discharge tubes—differential and common-mode surge suppression

Fusible series resistors—limit current and fail safely during extreme surges

Low-capacitance diode clamp—handles fast transients until gas tubes activate

This combination outperforms single-stage diode-only protectors

IP65-rated polycarbonate housing with clear lid—durable and weather-resistant, with easy visual fault detection

Supports AC/DC excitation and both 4- and 6-wire configurations

External ground clamp for reliable earthing

Designed to withstand 5 kA surge (8/20 μs), with stage-specific clamping: ~±90 V (stage 1), ≤1 Ω resistance (stage 2), ~±24 V clamp (stage 3)

Shielded 6-wire cage-clamp connectors and clear lid for quick troubleshooting

Compact polycarbonate unit (~160 × 80 × 55 mm, 340 g) suitable for field installation

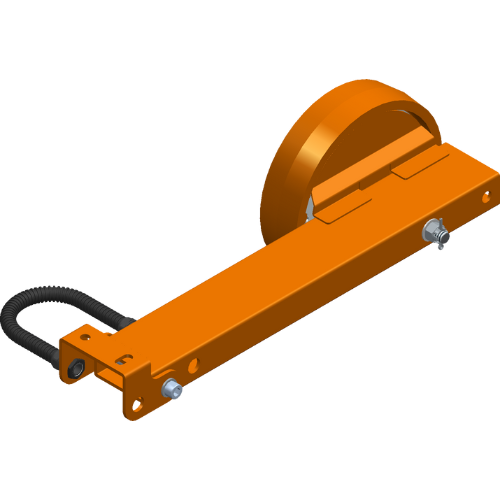

Designed to measure belt speed, especially when used alongside the LT1322 Tacho Meter.

Complements the LT1320 Belt Weighing Indicator, allowing for easy presetting.

Suitable for detecting metal objects in motion through contactless and wear-free sensing.

Ideal for integration in conveyor systems or belt-driven setups where speed tracking and object detection are required.

Wheel Diameter: 205mm

Output Options: PNP / NPN selectable by customer; default is PNP

Inductive Sensor Technology:

Detects metal objects using a high-frequency electromagnetic AC field

Field generated via RLC circuit with a ferrite coil

Pulse Rate: Determined by the belt speed per minute

Build Quality:

Constructed from alloy steel

Finished with powder coating

Uses off-the-shelf spares

Installation: Robust design, easy to install

Cost: Market’s most affordable Tacho meter

The LT1920 is a portable load cell simulator designed for:

Testing, troubleshooting, and calibrating load cell installations.

It is ideal for on-site diagnostic and calibration tasks where portability and accuracy are essential.

Simulates realistic load cell output signals to verify weighing system performance without requiring actual mechanical loads.

Portable design for convenient on-site use.

Generates fixed calibrated mV/V output step signals:

Nine total outputs:

Eight 0.5mV/V steps ranging from -0.5mV/V to 3.0mV/V

One additional step at 4.5mV/V

Equivalent bridge impedance: 350 Ohms

Accepts excitation voltage up to 15Vac/dc

Binding posts:

Color-coded to ISA S37.8 standard

Compatible with banana plugs or 14-gauge wire