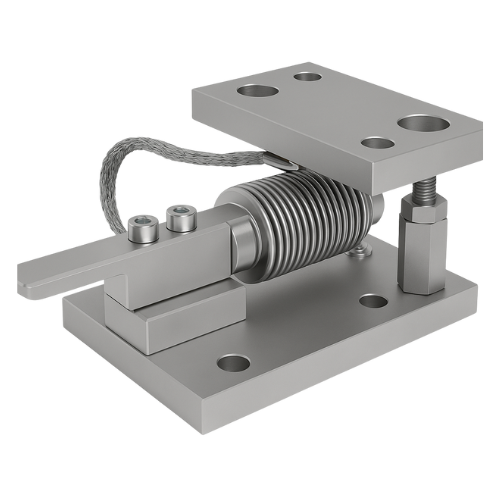

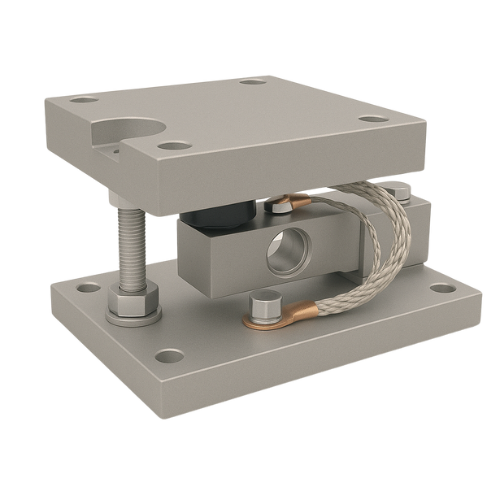

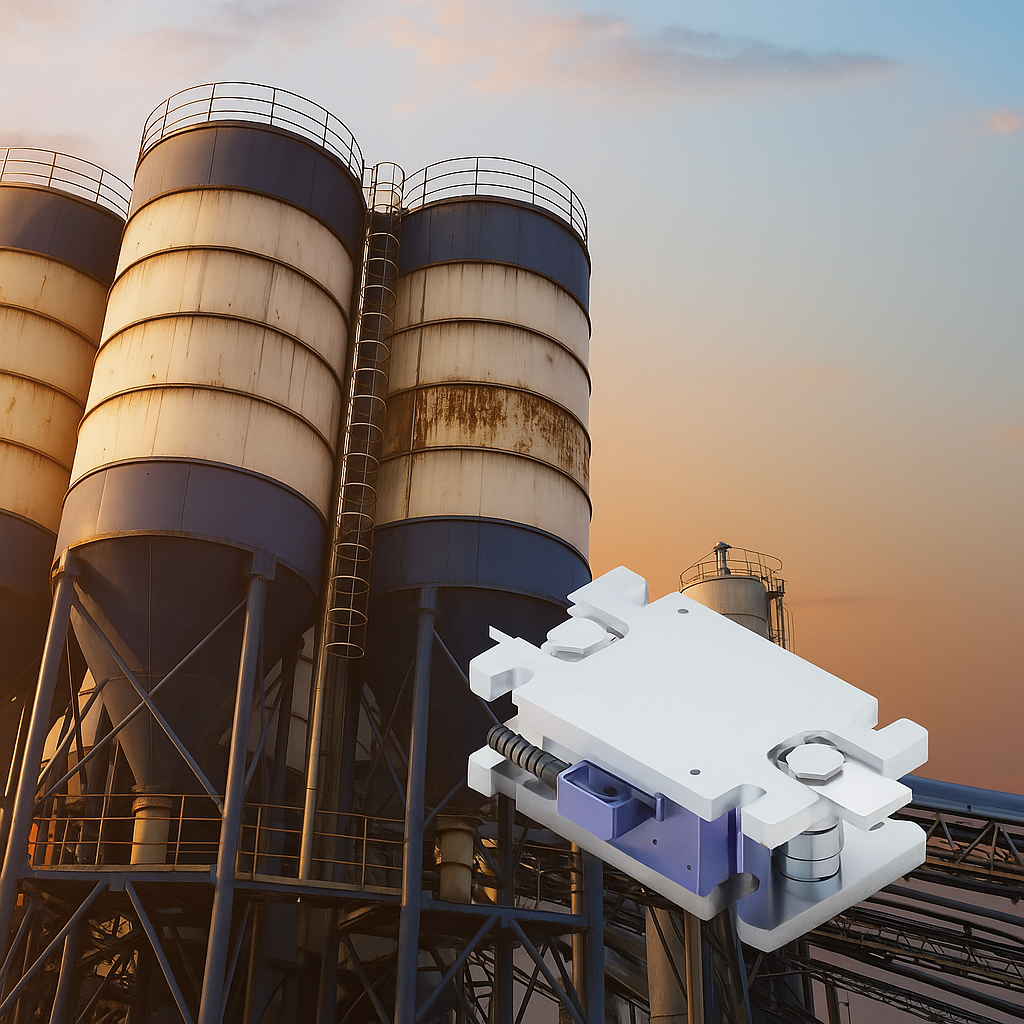

Weighing modules are mechanical structures that integrate with load cells to support and measure the weight of tanks, hoppers, silos, or other industrial vessels. They provide the physical mounting and safety features required for accurate and safe weight measurement in various applications.

Weighing modules house load cells to measure weight in static or dynamic structures. They ensure proper alignment, protect against side loads and vibrations, allow for thermal movement, and include safety features like lift-off protection and anti-rotation.

Strain gauges inside the load cells detect deformation from applied loads and convert it into electrical signals. The module design ensures these gauges operate accurately and reliably.

The module outputs an electrical signal proportional to the applied weight, enabling precise and stable weight readings under various conditions.